Mercedes-Benz Ponton 220S Sedan

Restoration Story / Part 4

by Terry Morgan / t_zmorgan@msn.com

Contents

-

Part 1 history

of the car / sub-frame removal / engine rebuilding

/ transmission rebuilding / front suspension rebuilding / brakes rebuilding

/ yet to do.

-

Part 2 engine rebuilding (oil pump, cylinder head) / transmission rebuilding

/ steering.

-

Part 3 engine compartment / front suspension / engine, drive train and

suspension installation / refurbishing heater boxes / reassembly of engine

compartment.

-

Part 4 engine compartment / heater boxes

(restored) / exhaust resonator / heater duct flaps / steering damper / brakes

/ rear axle / starting engine / rust repair / extra sound insulation /

suspension rebound stops / speedometer / cleaning fuel lines / fender straightening.

This is the story of the restoration of my 1959 220S sedan up through March 2001.

Engine Compartment

After installing the engine, (See part

3 of the story) I moved the car into my new shop and finished installing

all the engine compartment components. I forgot to replace the rubber

seals that go under the middle of the heater boxes and up the side of

the inner fender, so I got to remove the heater boxes again. The parts

place doesn't list new rubber seals. They said they are from "bulk material."

Mine were cast and though I would like new ones, they cleaned up adequately

to re-use.

Reconditioned heater boxes before installation

Exhaust Resonator

The donut gaskets on the header pipes

were pretty well bonded/rusted onto the pipes. They contain laminated thin

metal throughout that rusted and bonded onto the pipe. I had to chisel

the things apart, then use a chisel and tiny punch to clean out the crevice

where the gasket seals.

The "muffler" on the exhaust manifold was dented

and had some holes at the bottom end, though the pipes were sound. I checked

at a local muffler shop for something that could be retrofitted, but it

would be a bunch of trouble because of the two pipes coming in at one end.

Though it was probably possible to weld something up, I decided to see if

mine was repairable. Using a tiny cut-off wheel, I removed the outer metal

cover by cutting along the base of the pinch welds. I carefully removed the

asbestos insulation pieces. I set these aside where the fibers would not

be disturbed.

Resonator after cutting open, showing removed

cover piece and asbestos insulation

Using an air cut-off wheel, I cut out the rusted

and dented part of the resonator and sandblasted the inside and outside.

After sandblasting, I could even read the original supplier's name and part

number. It is interesting that it is divided into two halves internally.

Inside of resonator, before sandblasting

The top half is simply an open chamber where

the two pipes come in.

From body repair sheet metal, I fabricated

a new replacement piece and took it to a car restorer who welded it in.

I painted the whole thing with the high temperature silver paint from POR-15.

This paint "cures" at 350 degrees, so I cooked it in the oven. Don't do

this in your food oven unless you live alone and don't mind the very strong

chemical smell that will stink up the whole house. Though this paint will

rub off and marks easily before it is cured, it is very tough after curing.

I got some thin galvanized sheet metal and

fabricated a new outer cover piece. It was tricky to form the stepped ends.

I made a kind of form from metal strips and a hose clamp around a piece of

6" PVC pipe, then crimped the ends down over the "form" with pliers. I cleaned

the asbestos insulation (very carefully, outside, wearing a mask) and painted

it with the high temperature paint to prevent further fiber disintegration.

I had the same welder tack the cover together and to the resonator.

I used a piece of coat hanger wire to measure

the angles and length needed for a piece to connect the resonator to the

remains of my exhaust system. I took it to a local muffler shop where they

graciously made a connecting piece for free (though it took 3 tries and two

trips) and I promised to drive the car to them later for a whole replacement

system.

Heater Duct Flaps

After painting the ducts, I installed the air

flaps. I used some foam from those cheap foam paint brushes to replace the

foam seals on the flaps.

Heater duct flaps (after cleaning but before

the foam was glued on) and parts

Steering Damper

Jack Kotrba (thanks, Jack!) sent me

a used steering damper and I cut it open. As I suspected, they are not

designed to be rebuilt (well, I was hoping). It is possible to remove just

the ball joint end (in case it is kaput, but the damper is OK, remove the

crud around the narrow neck and drive out the small roll pin, then unscrew).

At the piston end, the metal case is machine rolled into a groove in the

aluminum end piece, so some careful cutting of the edge of this groove (using

a tiny cut-off wheel on a Dremel tool) will release it. Some good epoxy might

hold it back together, but without new seals and the correct replacement

oil, it's just an academic exercise. So I need to buy one or find a decent

used one.

I have heard a rumor that is it possible to use

a later damper (for a sixties MB that cost about $25) that has the "eye"

end at both ends. A special bolt adapts the eye end to the hole in the pitman

arm.

Brakes

I used the same front shoes but replaced

the rear brake shoes because they were oily and mostly worn out. I put new

adjuster friction washers on the rears - it was a bit of trouble to get

them loosened without the special wrench, but I managed to use a combination

of vice and open wrench to do it. Luckily, none were seized.

On each backing plate is a small aluminum

housing containing a pulley where the parking brake cable goes in, and cleaning

off the 40 year's worth of petrified dirt and grease reveals a nice aluminum

housing. I had to re-set the cable adjustment at the equalizing lever (right

above the drive shaft at the differential) to get enough slack in the parking

cable to allow me to connect the lever under the hood (I found out later

why the cable seemed so short - see the section below on first drive). That

was messy also, but it was an opportunity to remove and clean these parts

to like-new condition.

If you only need the rubber seals and don't

need the hard parts for your wheel cylinders, you can get replacement rubber

seals from any parts store that carries brake kits for American cars. Mercedes'

suppliers used inch sizes on the bores and seals, like most (all?) other

manufacturers. Just look at the size written on the seal and ask the parts

guy to look up something that uses that size (15/16"). My replacement seals

were for a mid-sixties Chevy and cost about $3.00 for each corner. Note on

the seals: there are two basic designs: with and without an "expander" piece

to help expand the seal against the bore. If the new seals don't come with

expanders (as did the originals), don't use the old expanders and instead

use the custom springs that come with the new seals.

I replaced the rear flex hoses without any

grief. The fronts also came off easily, but they had been removed around 1980.

I bled the brakes with my vacuum pump system,

but there was still some air somewhere. Got my wife to help do it conventionally

and the air was in the fronts.

Rear Axle Bearings and Seals

I removed both rear axles to replace

the two seals around the bearing on each side. To get the axles off, you

need to remove the brakes, remove the 6 to 8 (?) small bolts that attach

the bearing retainer plate and brake backing plate, and then tap out the

axle with a slide hammer. It came out very easily (though it's a little messy).

Getting the bearings off the axle took some doing - I took them to a friend

who has a press and it took significant rigging with spacers, blocks, angle

metal, etc., to rig it properly to push the bearing off. The bearings must

come off to replace the outer seal (in the retaining plate). The right bearing

had been noisy since I bought the car. Sure enough, it was badly pitted.

Miller's MB supplied the new bearing, locking washers for the bearing retaining

nut, inner and outer seals, and paper gasket (these parts are relatively cheap).

Getting the inner seal installed in the axle

tube was also a bit of trouble without the special tool. If you replace this,

have someone with a lathe make you a proper tool to drive it into place -

it will be worth it. Use a thin coat of silicone sealant around the outside

edges.

For installing the outer seal into the retaining

plate, I made a "press" with some small plates of metal and used my vice

to press the seal into place. This way it gets pressed in squarely and doesn't

damage the seal. I used the old seal to press it the final few millimeters.

Then, while installing the axle, I discovered that

I installed one of the bearing retaining plates (and the seal in it) backwards

and had to do one axle all over again! Well, it sure LOOKS like it should

go the other way. :-(

Engine Start

Before I set the timing, I fabricated

a rod that fit down into the distributor hole and engaged the oil pump.

I spun this with a drill to prime the oil galleries. This worked well except

for a spill where I had loosened the fuel pump so its plunger would not

be activated (this made it easier to spin the pump). Surprisingly, this

place gets well flooded with oil and I had to mop up about a half quart

of oil.

The gas tank is not yet installed, so I

used an oil bottle for gas and a line to the fuel pump. I held a rag around

the top of the bottle and pressurized the bottle with an air nozzle to force

gas through the pump and into the carbs. This primes the pump and saves

the starter.

I statically set the timing and checked

all the wiring. New battery, hooked it up, looked for sparking on connection;

OK. Tried the starter for a second; OK. Checked for gas at the carbs; OK.

Checked for accelerator pumps squirting; NOT OK. So removed the accelerator

pump diaphragms and cleaned; about two hours of fiddling around and cleaning.

Reinstalled; OK. Tried the starter and instant vroom! Nice! No strange noises,

no leaks; OK. After a minute or so it even idled on its own. Ran it until

it fully warmed up, then shut it off.

The next running was a few weeks later when I drove

it up and down the street a few times. No front fenders yet, so no lights;

no gas tank so can't go far anyway! Brakes work OK, stops straight. Some

noises from drive line when coasting; later investigation on my lift showed

the parking brake cable was wrapped once around the drive shaft, so I had

to take the lever off to unwrap it from the front half of the shaft. If that's

all I did wrong, I consider that good!

Rust Repair

After cutting away all the badly rusted

metal at the bottom of the front door posts, I got some 16 gauge body sheet

metal repair stock and then cut and shaped metal pieces to fit. The required

trial and error is rather tedious, which is why rust repair can quickly

run up big $$ -- good thing I work for free. A restorer friend will bring

his welder to weld these pieces in before I replace the fenders.

Jack also sent me new door hinge screws

and a new screw plate. I had to drill out several of the rusted screws.

I added an "x" brace to the radiator frame.

I had long noticed that the whole front end would shake side to side on

severe bumps, and I noticed that Kevin Clemens added the same kind of brace

to his "Around-the-World" rallye car. I got some screen door adjusting rods,

cut them and beveled the ends, and made a small depression where they will

be tack welded to the lower front cross member in front of the radiator.

The spot welds to the right side of the

inner fender are partly rusted and partly just broken, so those will be

re-tacked by my welder.

Extra Sound Insulation

I put foil lined jute sound insulation

on the bottom of the floor boards, under the rear seat, behind the stock

cardboard panels below the windshield, and behind the driver and passenger

side kick panels. I got the stuff from an upholstery shop and they gave

me some glue for it also. I will get another piece for the underside of the

hood. When I take the door panels off, I plan to put some on the inside of

the doors.

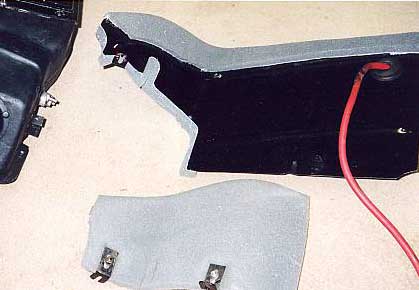

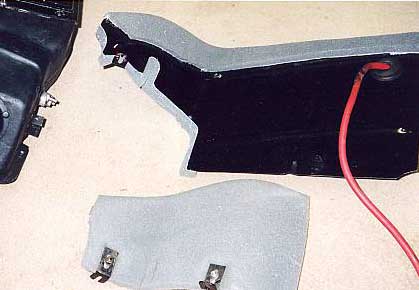

Foam Sound Deadening

The car originally had sheet foam glued to

the back of the metal panels above the firewall. I found an upholstery

trim shop that had some gray foam with cheesecloth backing that is a reasonable

replacement. They also sold me a spray-on contact adhesive that made it

very easy to apply the glue.

Foam insulation on firewall pieces

Kick Panels

The cardboard panels on the sides of

the front foot wells were damaged by moisture that entered through the rusted

out areas behind the wheels. You can get cardboard replacement stock but

it is not the original color or texture. I got some vinyl of the proper color

and I plan to wet the bottom of the panels (the only area they are deformed),

mold them back to a flatter shape, and glue on the vinyl.

Suspension Rebound Stops

I got new rubber front suspension droop

stops, but not before the suspension was assembled and installed. Putting

these in is a pain - do it before installing the upper A-arms. I jacked

up the car so the upper a-arm would help push the tab through (with a little

grease on it), but I had to use a string under it to pull on the side that

didn't start through, and, while working upside down, try to pry the rubber

so it would come out through the hole, all the while adjusting the jack

for more or less pressure on the top. Good thing the fenders are not in

the way!

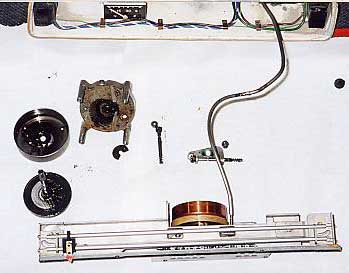

Speedometer

Once in the past, my speedometer filled with

grease and indicated many times higher than it should. The grease was pumped

up the drive cable (like an Archimedes screw) and filled the drive mechanism.

The drag on the grease is like a viscous drive coupling (normally, there

is air between the spinning magnetic disk and the driven cylinder) and makes

the speedometer read very high - it pegs out when going only about 20 to

30 mph, depending on temperature. It had happened again just before I disassembled

the car. The inside of the speedometer is a fine piece of craftsmanship

and assembled like a fine instrument.

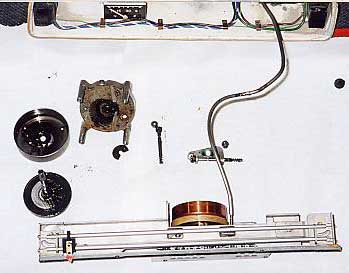

Speedometer pieces after disassembly

and before cleaning. Disk (lower left) shows grease that got inside, half

wiped off. Cylinder for disk above, with grease inside. Die-cast drive

piece to right. Cable is for odometer reset. Small gears are for odometer

drive.

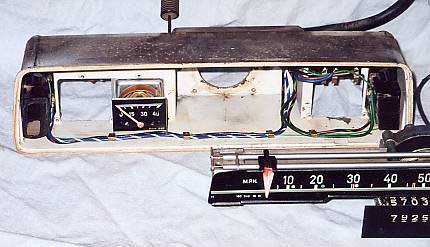

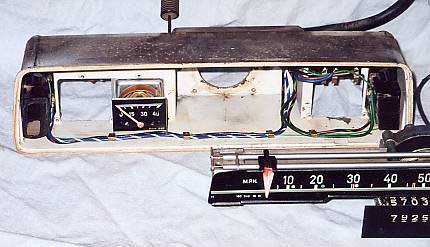

Front of speedometer case

The indicator needle is moved by a VERY thin wire (about the

thickness of a human hair) that is wrapped around a spiral-grooved drum

that is driven by the spinning input disk. Pulleys at each end guide the

wire around the ends of the scale where the guide rods for the indicator

needle are attached.

Back of speedometer mechanism, gauge mask,

gas gauge, and lamps

To Disassemble the Speedometer

- Remove the speedometer unit from

the dash. Despite what the manual says, you don't need to totally remove

the temperature gauge capillary tube from the car; you only need enough

slack to be able to remove the 3 screws on the back that attach the

temperature gauge (though it's a little difficult working backwards

and blind while trying not to scratch the dash or steering column).

- Carefully pry the chrome surround

off the case, starting at one end. It doesn't need to be bent significantly

to remove it, but having three hands helps.

- Remove the glass. It's held with

sticky tape so it may take a small suction cup to get a grip on it.

Remove the mask for the scales.

- Remove the four screws in the

back that attach the speedometer drive mechanism and remove the speedometer

and mechanism with scale.

- Remove the screws in the back

that hold the drive mechanism on. Watch for washers and spacers, especially

the very tiny washer on the pin that centers the driven cylinder on

the spiral drum.

- There is a thin metal washer

and a thin rubber washer sandwiched behind the die-cast piece (that

holds the shaft of the spinning disk, where the speedometer cable

attaches) and the cylinder that houses the spinning disk. I think

the rubber seal is supposed to keep any oil or grease from getting

past, and there is a groove on the back of the cast piece that will

let the fluid out to the side. To repair the worn rubber washer, I

put some silicone sealant on it when I reassembled.

- Behind the odometer scale on

the left side, under one of the screws, is a piece of metal that acts

as a stop for the return spring. When reassembling, adjust this so

the needle rests exactly on zero.

- Use a soft camera lens cleaning

brush to clean the scales and other parts.

- One of the pulleys is mounted

on a separate piece that allows adjustment of the tension on the wire.

There is a tiny tension spring at one end of the wire where it attaches

to the indicator needle. This spring was completely slack, so I loosened

the screw and moved the pulley outwards a little to take up the slack.

- The speedometer is calibrated

via an adjustment nut (located behind the scale and below the spiral

drum) that adjusts the tension on the main spring that returns the

needle to zero. If you have a way to accurately spin the input shaft

so the odometer increments one mile every 60 seconds, you can adjust

the tension spring so the needle reads 60 mph (1 mile/minute). (I did

not try this and I suggest you use a speedo repair shop.) You cannot

"calibrate" the odometer because it is direct drive at a fixed ratio. If

you need to calibrate your odometer and speedometer to your car because

you have tires of a different diameter than stock, you need a small

gearbox that connects between the transmission and the speedo cable

to change the overall ratio. These used to be available in various ratios.

- My sandblasting of the engine compartment

managed to get some sand inside the speedometer case (I'm sure I'll

be finding sand in strange places for years to come?). There are holes

in the tiny rivets along the bottom that hold the clips for the wiring,

and gaps around the holders for the indicator lights. I these filled

these openings with little dabs of caulking.

Back of speedometer housing and instrument,

before reassembly. Adjustable pulley end for tensioning the wire is visible

on left end of speedometer mechanism

Cleaning the Fuel Lines

The fuel lines had lots of "varnish"

from ancient dried-up fuel. To clean out the lines, you can use spray carb

cleaner or lacquer thinner (paint thinner won't cut it). I took the fuel

filter out of the reserve selector and put the end of the hose into a beer

can to catch the fluid. I sprayed carb cleaner into the rear end of the line,

using a rag to seal the spray tube around the line. If you use lacquer thinner,

you can run a hose from the fuel line into the bottle and use compressed air

to carefully pressurize the bottle to push the fluid into the line. Then blow

out the line thoroughly. Warning: if your fuel selector is still installed

in the engine compartment, one of the lines is not open at that end (depending

on the position of the selector) - if you pressurize this closed line, the

fluid will shoot back out into your face when you release the pressure! You

DO NOT want to get this stuff in your eyes!

Fender Straightening

Using a come-along, I hope to straighten

the inner fenders that are a little bowed out from the collision the car

had at some point in its early history. I had always noticed that the front

fenders seemed to bow outward over the wheel openings more than they should.

When I put the hood on without the fenders, I could see that the top edges

of the inner fenders were not parallel with the sides of the hood. I'll describe

how this goes in a future installment.

Created: April 16, 2001

© www.mbzponton.org

Return to the Ponton Workshop page