Mercedes-Benz Ponton

Hydrak Automatic Clutch

Hydrak = hydraulische kupplung

Development and Implementation

Hydrak = hydraulische kupplung

Development and Implementation

The idea behind the automatic clutch technology is to provide an experience that requires driver input, and therefore is interactive rather than passive, but also eliminates the need to disengage the clutch repeatedly in city traffic. The name Hydrak itself comes from the German words hydraulische kupplung (hydraulic coupling). The Hydrak was co-developed by Fichtel & Sachs and Daimler-Benz AG for use in the 6-cylinder Mercedes-Benz Ponton sedans, coupés and cabriolets. It was a factory-original, extra cost option, which consisted of a synchronized, column-shifted, four-speed transmission with an automatic clutch. Furthermore, the clutch, control valve assembly, and the servo unit were made by Fichtel & Sachs. The fluid coupling was made by Daimler-Benz. It was first available in 1957 on the Type 219 (1957-1959), Type 220S (1957-1959) and the Type 220SE (1958-1960) models. The system served to bridge the gap between having a fully manual and a fully automatic transmission. The Hydrak option originally cost DM450 (450 Deutsche Marks). The 4-cylinder Ponton models were not offered with this feature.

The Hydrak never became an equipment detail that was particularly liked, which made the Stuttgart engineers distance themselves from further development after using it in the W111 Heckflosse (fintail) models Type 220b / 220Sb / 220SEb (1959-1961). Because the system depends upon a combination of vacuum and electrical components to function properly, the potential for wear and other problems is fairly high. Many owners became dissatisfied with the systems when they began to develop problems, and because of this, converted the cars to manual transmissions. For many years after the last Hydrak equipped Mercedes-Benz models were sold, complete conversion kits with all the parts needed to make the modification were available from authorized agents. A word of caution: Some price guides will suggest you deduct a certain amount from the value of the car if it still has the Hydrak option installed. However, from the point of originality it should be carefully operated, maintained and preserved.

Several other German automobile manufacturers such as Volkswagen and Porsche also adapted the use of Ficthel & Sachs automatic clutch units. The Volkswagen "Automatic Stickshift" adaptation did not appear until later in the 1960s which was well after Daimler-Benz had decided to cease development. In 1969, Porsche used the name "Sportomatic" to identify the usage of the automatic clutch in the their Type 911e model. The unit that was used by Mercedes resembled the Fichtel & Sachs "Saxomat" clutch, which was used, without a hydraulic torque converter, by Opel and DKW-Auto-Union.

Identification by Chassis Number

The existence of a Hydrak as original equipment can be determined by checking the chassis number of the vehicle. The structure of the chassis numbers changed in 1959 so there are two possible ways to identify the Hydrak. Reference the Chassis Number page for details.

From a marketing standpoint, it was important to include this particular technology with the models that were exported and distributed in America through the Studebaker-Packard dealerships. This section will put forth several potential reasons as to why why automatic transmissions were not further along in development in 1950s Germany. At the time the Pontons were being produced, the only Mercedes-Benz production passenger vehicle that offered a fully automatic transmission was the Type 300 "Adenauer" limousine. From 1955, the Type 300 could be special ordered with a Borg-Warner 3-speed automatic. Why did Daimler-Benz wait until the 1950s and 1960s to develop and adapt the automatic clutch, and later, fully automatic transmissions in their passenger vehicle range? One reason is that the smaller engines used in German vehicles during the years following WWII did not have much power to squander. A manual transmission is more efficient than an automatic. They give better mileage, as well as being quicker than the same car with an automatic transmission. They are also cheaper to manufacture. Automatic transmissions lose power because they have a fluid interface (coupling). They pass the power from the engine to the drivetrain through the transmission oil. Manual transmissions lose less power because they rely on two (clutch) plates pressing tightly against each other to transfer the power. The amount of power an engine can generate and the amount that actually reaches the wheels is always different. The power that reaches the wheels is always lower because of parasitic losses in the drivetrain. As a general rule of thumb, the transmission, drive shaft, and differential take 10-15% of the power from the engine. Those vehicles with automatic transmissions will usually have an even greater loss in power. Unlike so many of the large 6 and 8-cylinder engines found in American cars of the 1953-1962 period, the smaller less powerful engines designed for domestic duty in Germany could not afford the power loss associated with the fitment of an automatic gear box. The Hydrak was a compromise between the efficiency of the manual transmission and the simplicity and luxury of using an automatic. It represents a distinct phase in the development of the automatic transmission in German passenger vehicles of the era.

To illustrate the difference in engine sizes, recall that the "standard" engine size on many American cars was 5.7 liters (350 cubic inches) with certain optional engine sizes displacing another 30% in volume. Engines in Mercedes-Benz Pontons ranged from 1.8 liters (109 cubic inches) to 2.2 liters (134 cubic inches) and had far less power to spend on inefficient devices like automatic transmissions. However, there was still a large market for a car that was perceived to be easier to operate than one with a 4-speed manual transmission.

Manufacture and Adaptation of the Hydrak

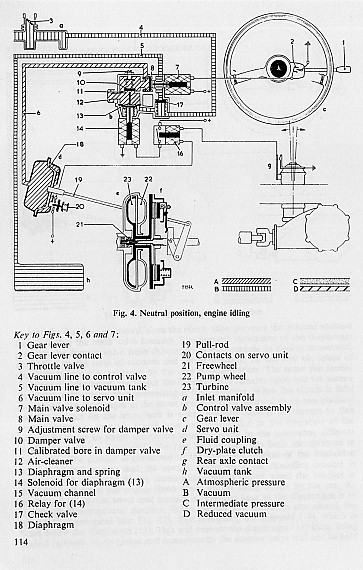

Schematic of Hydrak system. Neutral position, engine idling

From the factory's perspective, a distinct advantage of adapting the Hydrak to the Pontons was that it could be used in connection with the already existing 4-speed manual transmission. While the driver operated the shift lever (standard H-pattern), there were only two pedals (accelerator and brake) in the floor space. When moving the shift lever, a sensitive electric switch at the base of the lever actuates a vacuum servo, which engages and disengages the clutch. The shifting process is buffered by a fluid coupling. A refinement in the system was a switch which controlled the engaging of the clutch as a function of whether the car was accelerated, braked or idling. A supplemental pamphlet was issued with the owner's manual of Hydrak equipped cars which included correct driving and maintenance instructions. A problem arose with drivers who did not follow the prescribed usage of the system. If the driver treated the system like a normal automatic transmission, thus when switching gears not removing the foot from the gas pedal, it would result in rather poor shifting, and the clutch wearing out prematurely.

Driving with the Hydrak System

The Hydrak includes a vacuum operated clutch which is electrically activated whenever the shift lever on the steering column is touched. A fluid coupling allows stopping and idling without disengaging the clutch. The clutch pedal is omitted on cars equipped with the Hydrak; however the gear must be changed in the usual way (standard H pattern) by means of the gear lever, since these cars are not equipped with an automatic transmission. During long pauses or when idling the engine in a stationary position, the gear lever should be placed in the neutral position. After the gear is selected, the gear lever on the steering column should be released immediately and it should not be touched during driving, except for the purpose of changing gears. The clutch will disengage immediately the moment the gear lever is touched. When driving off from a standstill on an upgrade, always use first gear. The left foot actuates the foot brake, thus keeping the car stationary, the right foot actuates the gas pedal so that the car will not roll backwards. Now the left foot may be removed from the foot brake. When actuating the gas pedal the car automatically drives off. The acceleration depends on how far the accelerator pedal has been depressed. It is recommended that driving off from a stop on level ground should be done from 2nd gear.

A problem that the Stuttgart engineers had not counted on was the driving habits of the average owner. It was important to remember to lift the foot from the accelerator pedal when changing gear, just as in a normal three pedal car, and failure to do so could produce some interesting kangaroo effects and rapid wear on the clutch friction lining. Likewise, the natural tendency to leave one's hand on the gear lever between shifts would actuate the clutch, with similarly undesirable effects. The clutch will not engage as long as the gear lever is held by hand. This also created unnecessary wear on the components of the system. Although the Hydrak was a popular option on its introduction, cars fitted with it were difficult to sell on the secondhand market in later years.

Maintenance

The fluid coupling is filled with automatic transmission fluid. Use Dexron III, as the original "Type A" fluid is no longer available. The fluid level in the coupling should be checked every 4,000 miles. The fluid level is checked by removing the inspection cover in the central floor tunnel and open the inspection cover on the clutch housing. Turn the crankshaft until one or both plugs on the fluid coupling is facing the inspection hole. Unscrew the plug two or three turns and wait until pressure in the fluid coupling is released. Now remove the plug. Be careful not to drop the plug in the clutch housing, since in that case the transmission and fluid coupling will have to be removed. The fluid level should be flush with the lower edge of the filler plug opening. Top up with automatic transmission fluid if necessary. Refit the plug with a new seal ring. Total capacity is 1.5 liters. Periodic draining and refilling of the coupling is not necessary. The air screens on the flywheel housing should be cleaned every 4,000 miles. The upper screen can not be removed and must be cleaned by wiping it with a clean rag.

|

Mercedes-Benz |

||

| Pages 11-20 | Pages 21-32 | |

Hydrak Brake Pedals

Pontons equipped with the Hydrak have a different brake pedal from those without the system. The cars which were fitted with the Hydrak automatic clutch have three different styles of brake pedal. The two early style pedals are larger than the later style. The smaller, later style brake pedal in Hydrak equipped models is the same size as cars without the Hydrak system. In other words, they use the same rubber pedal cover as found on the clutch and brake pedals in all other Ponton models.

The two early (larger) style brake pedals in Hydrak equipped cars are broken down: up to serial # 7511393 the cars use pad part number 186-292-02-82 and from serial # 7511394 through # 8503174 the pad part number is 180-292-00-82. After that serial number, they all use the same size brake pedal cover (part number 319-292-00-82) as found on the clutch and brake pedals of the rest of the models in the series.

The photo above is from a Type 220S sedan (chassis number 180.011-Z-7513379) owned by Bob Gunthorp. It includes the larger brake pedal which was a feature of cars equipped with the Hydrak system. It does not have a separate clutch pedal. This type of pedal can also be seen in the brochure illustration above. Note in both this photo and the brochure above, the accelerator pedal has no cover. The year of manufacture can be determined by reversing the first two digits of the last group of numbers (7513379) in the chassis number, thus revealing a build year of 1957. The "Z" in the middle of the chassis number confirms that the car was equipped with the Hydrak. This car was probably manufactured in late 1957 and sold in the year 1958. In Germany, a vehicle is registered according to its year of manufacture, not the year it is sold.

This is the brake pedal from Graham van Heerden's original, unrestored 1958 Type 220S coupé. The car has 96,000 miles and is equipped with a Hydrak. Note the original woolen carpets. This South African Ponton has a chassis number of 180.037-Z-8501272.

Here is a brake pedal from a 1958 Type 220S sedan, body number A180.010-8504461 (owned by Bill Vickery) with the Hydrak system. Note the hole for the clutch pedal has been sealed with a removable rubber plug. This well worn brake pedal cover still has some of the original tread pattern left.

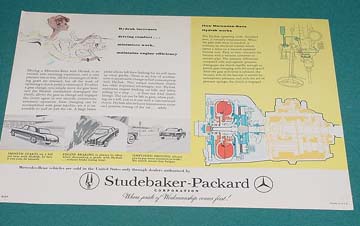

Hydrak two-sided Brochure

Page 1

Hydrak...Mercedes-Benz Automatic Clutch

1st Gear - No Clutch

2nd Gear - No Clutch

3rd Gear - No Clutch

4th Gear - No ClutchThe most advanced automatic clutch in the world

For years, it has been the ideal of many motorists to eliminate the clutch pedal and still retain a full selection of gear ratios that can be selected at will by simply shifting gears. This enables the driver to use maximum engine power at all times, aiding maneuverability under adverse driving conditions and in traffic. Now this is possible with Hydrak, Mercedes-Benz new hydraulic-automatic clutch. Since there is no clutch pedal, you can change gears instantly, smoothly, easily, without moving your left foot. Every gear change -- forward or reverse -- is swift and silent. Hydrak is truly a remarkable mechanism. It makes it impossible to jerk the car, even with starting on grades. Jolting when changing gears and stalling at starts and stops is also a thing of the past with Hydrak.

Page 2

Hydrak increases driving comfort...minimizes work, maintains engine efficiency.

Driving a Mercedes-Benz with Hydrak is an entirely new motoring experience and a very pleasant one at that. All the advantages of shifting gears are retained, but all the work of operating a clutch pedal is eliminated. To effect a gear change, you simply move the gear lever and the Hydrak mechanism disengages the clutch, allows the gear to change and engages the clutch again in one smooth continuous automatic operation. Gear changing can be accomplished with great rapidity, yet it is impossible to stall or jerk the car. A large brake pedal allows left foot braking for no-roll starts up steep grades. There is no loss of acceleration or appreciable change in fuel consumption with Hydrak. This unique automatic clutch has other important advantages, too. Hydrak maintains engine braking on hills and when rolling to a stop ... but does not wear clutch linings. The car can be left in gear when parking on a hill just as it can with a conventional clutch. Hydrak also reduces transmission noise and permits towing of the car....safely.Smooth starts on a hill are easy with Hydrak. In fact, they can only be smooth.

Engine braking is always in effect when descending a grade with Hydrak... reduces brake lining wear.

Simplified driving allows you to pay more attention to traffic. No clutch means less fatigue.

How Mercedes-Benz Hydrak works

The Hydrak operating cycle, described here, is virtually instantaneous. When the gear shift lever is touched, it activates an electrical contact which opens a valve on a vacuum-operated booster unit. This in turn connects the booster with a vacuum container or suction pipe. The pressure differential compared with atmospheric pressure, disengages the clutch rapidly enough to permit gear changing with usual speed. After the gear shift lever is released, the vacuum side of the booster is vented by atmospheric pressure, and with the aid of pressure springs, the clutch is engaged.Mercedes-Benz vehicles are sold in the United States only through dealers authorized by Studebaker-Packard Corporation.

Daimler-Benz Automatic Clutch (Hydrak) two-sided Brochure

Parts needed to change a 220S Hydrak clutch to a standard clutch

Flywheel

Clutch disc

Pressure plate

Clutch release bearing

Complete bell housing with release fork and cover plate and any other items attached

Transmission input shaft

Transmission cover front

Front half of drive shaft

Clutch pedal with linkage and return spring

Shift lever

Shift linkage

Annular nipple (vacuum fitting on brake booster) you could plug the line to the vacuum container.

You may need to change the alignment pins between the engine and bell housing.

References / Acknowledgements